VISUAL AND THERMAL FLARE INSPECTION

ROAV7 inspects flares and flare tips using UAVs. Thanks to their high definition and thermal cameras, our UAVs collect quickly required datas without interrupting the activity to see and analyze flare tips, shields and access roads. We can intervene to dispel any doubts on an identified issue, or prepare a production shutdown several months in advance.

We deliver to our clients inspection reports:

- High definition building pictures

- Thermal analysis of heat problems

- 3D modeling exposing buildings distortions

In emergency situations, ROAV7 can easily and quickly diagnose to instantly dispel any doubts about buildings, flare tips, shields and access roads.

INSPECTING FLARES USING UAVs

ROAV7 can easily access flares avoiding human risks, production shutdown and precisely analyze facilities.

No production shutdown

UAVs operate on running flares allowing low-cost diagnosis.

Safer

Using UAVs reduces risks for high up-related working accidents by avoiding specialized technicians to inspect directly the flares.

Faster

UAV flights last a few minutes. From a half-day to two days of site operations are enough to precisely and fully inspect the flare.

More accurate

The whole flare is photographed in high-definition. The buildings’ pictures are taken at the moment enabling a clear view of elements and anomalies and recording the entire flare.

life-cycle.

Easier to operate

ROAV7 teams operate with a two-men team and one backpack carrying the UAVs and the remote control. A minimalist equipment for fast interventions.

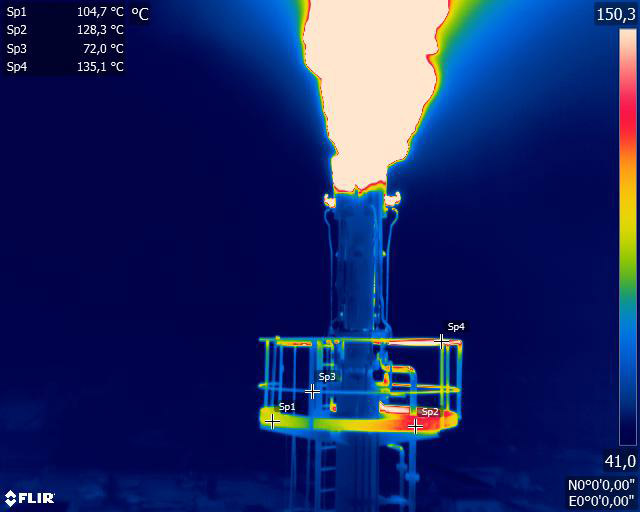

CASE STUDY : FLARE INSPECTION BY UAV

FPSO Flare inspection in Congo and Angola

ROAV7 visually and thermally inspected four FPSO flares off the coast of Congo and Angola. Detailed data acquisition of the flares structure was realized with a safety distance of 20 to 40 meters and a 120-meter altitude.

ROAV7’s client became aware of sensitive facilities deteriorations such as the flare tip and disorders at a centimeter scale. These inspections made the oil operator able to update his intervention agenda following the acquisition results, without production shutdowns.

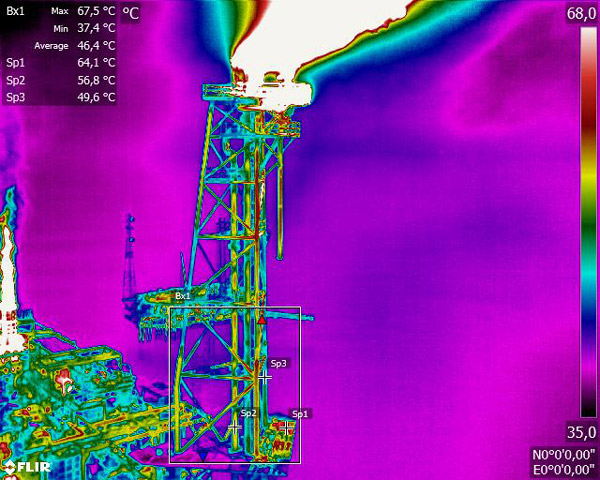

CONGO : ROAV7 ANALYZES THE OIL DEPOT FLARE

A visual and thermal flare inspection conducted by ROAV7 in Congo to dispel any doubts following a potential anomaly. Without shutting down, waiting for the structures to cool down and sending men with cords, inspection and maintenance services were able to assess the situation based on UAV images.