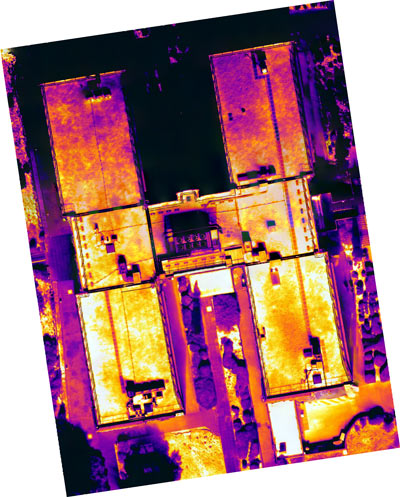

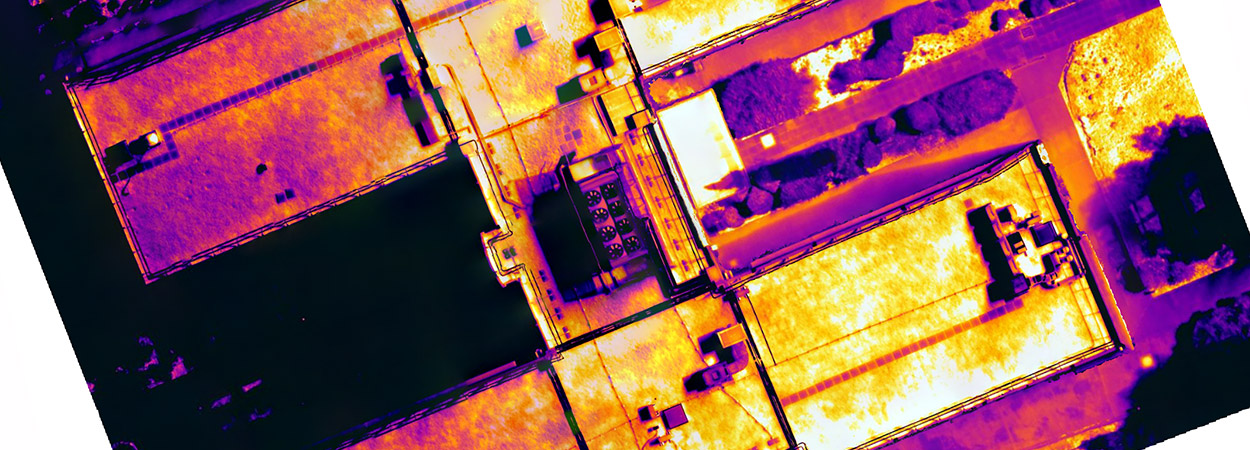

THERMAL INSPECTION

With their thermal cameras, ROAV7’s UAVs quickly fly over a huge area of structures or flight close enough to them for a detailed inspection.

UAV thermal inspection enables us to remotely measure temperatures, analyze heat problems, detect gas and liquid leaks and heat discrepancies. ROAV7 operates on buildings, industrial facilities, flares, pipelines, solar farms and photovoltaic panels.

DETECTING FACILITIES VULNERABILITY

No production shutdown

Without shutting down the production, a UAV thermal analysis enables us to detect leaks, structures’ heat problems and early signs of weaknesses.

Safer

UAV thermal inspection enables us to detect anomalies beforehand to avoid real problems, breakdowns or accidents.

Faster

A thermal camera can detect oil and gas leaks and directly assess reliable assets.

More accurate

UAV thermal cameras take accurate pictures based on different detected temperatures.

Easier to operate

ROAV7 teams operate with a two-men team and one backpack carrying the intervention equipment. ROAV7 interventions are fast, accurate and do not require complex deployment.

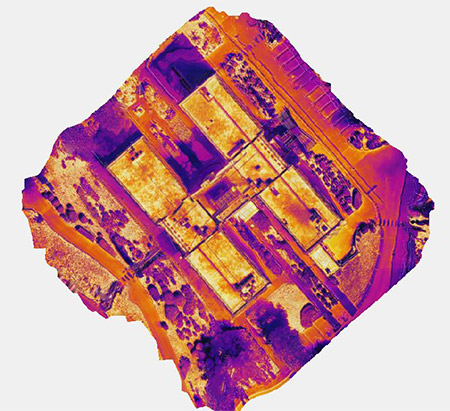

STUDY CASE : UAV THERMAL INSPECTION

ROAV7 often thermally inspects flares by UAVs in Congo.

After a visual inspection of the flare and the platform revealing escaped fragments from the flare tip, ROAV7 realized a 3D-model of the flare tip, which was roughly distorted and torn.

A UAV thermal analysis completed the inspection to detect heat problems of the structures and determine the hot spots of the flare tip.

Our client was able to operate efficiently for his next shutdown and optimize the technicians’ intervention.